QTJ10-15 Fully Automatic Concrete Block Making Machine

It is equipped with PLC control system. And all the mould can be made by customers’ drawings. The key parts are famous brand electrical parts, to guarantee good quality. So if you need a high capacity and fully automatic block making machine, the model QTJ10-15 is the best choice for your block production project.

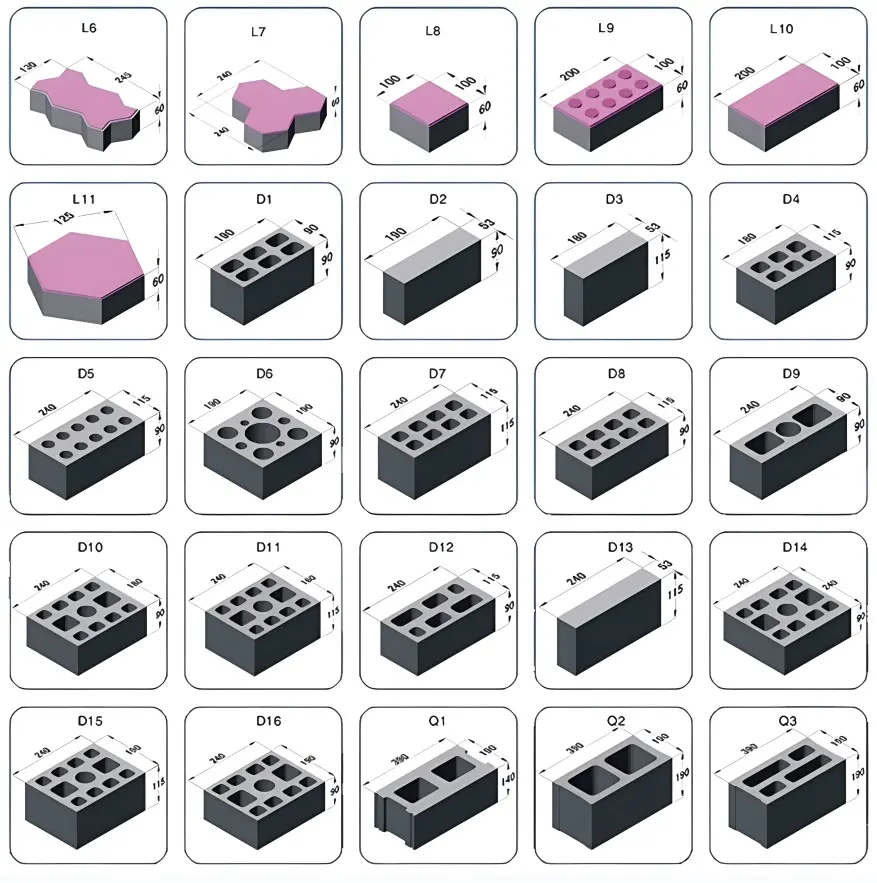

By changing molds,many kinds of blocks can be made as follows:hollow blocks,holland bricks. curbstone , Standard bricks, Cellular bricks, Grass brick, Decoration bricks, Pavement bricks .

Automatic operation with PLC controller and hydraulic system .

Components of QTJ10-15 Automatic Concrete Block Making Machine :

| No. | Components | Pcs |

| 1 | B500*8 Belt Conveyor (For Raw Materials) | 1 Set |

| 2 | JS-750 Twin-shaft Concrete Mixer | 1 Set |

| 3 | QTJ10-15 Block Making Machine | 1 Set |

| 4 | PLC Control System | 1 Set |

| 5 | Spare Parts/Tools | 1 Set |

| 6 | Manual Block-transportingCarts/Push-carts | 3 Sets |

| 7 | Block Stacker Machine | 1 Set |

Specification:

| Overall Dimension | 7564×2060×2950 mm |

| Main Vibration Form | Platform |

| Forming Time | 15-20s |

| Motor power | 54KW |

| Weight | 15T |

| Pallet Size | 1150×900×30 mm |

| Mixer Type | JS750 |

| Voltage | 380V/440V,50/60hz |

Production capacity :

| type | size | pcs/mold | molding time | pcs/hr | pcs/day (8hours) |

| hollow | 400*150*200mm | 14pcs | 15 seconds | 3,360pcs | 26,880pcs |

| hollow | 400*200*200mm | 10pcs | 15 seconds | 2,400pcs | 19,200pcs |

| porous | 240*115*90mm | 24pcs | 15 seconds | 5,760pcs | 46,080pcs |

| solid | 240*115*53mm | 54pcs | 18 seconds | 10,800pcs | 86,400pcs |

| paving | 200*100*60mm | 35pcs | 18 seconds | 7,000pcs | 56,000pcs |

| paving | 200*160*60mm | 24pcs | 18 seconds | 4,800pcs | 38,400pcs |