QTJ4-15 Automatic cement brick making machine

This automatci cement brick making machine is very hot-selling model around world . Easy for operation and maintenance, applied for different types concrete block, solid/hollow/cellular masonry products .

Advantage:

- Fully automatic and hydraulic,large production capacity.

- Siemens electric PLC control system and motor.

- Heat treatmet on brick mold and main parts, with stability performance and reliability in the long-term running .

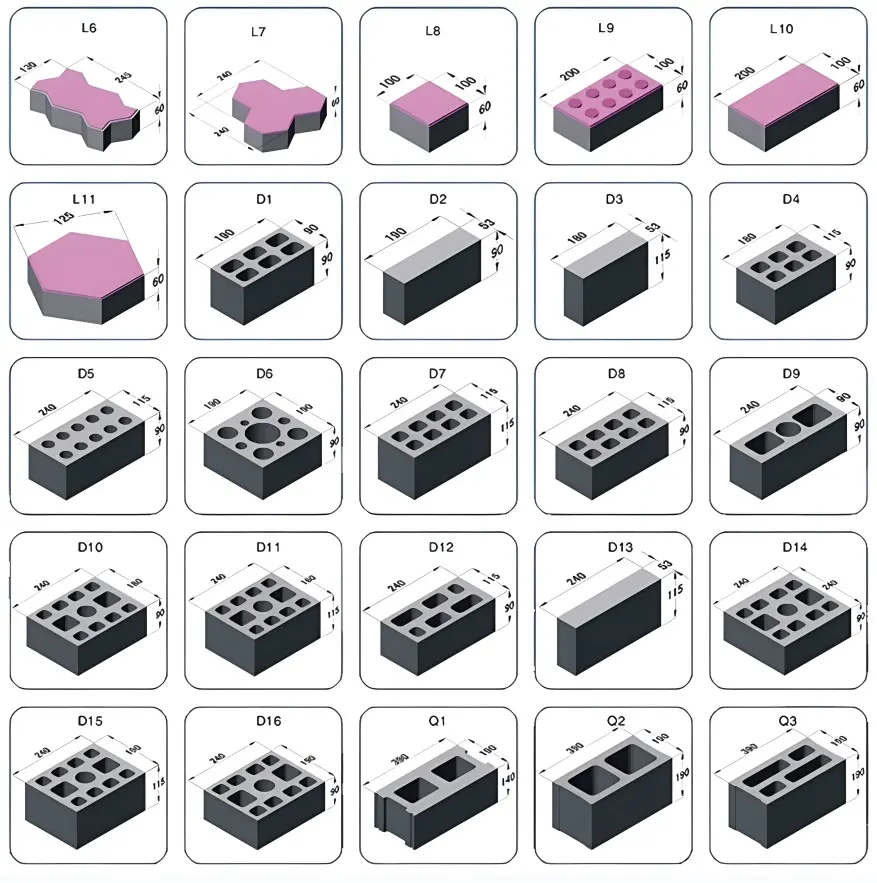

- Can produce hollow brick ,solid brick, paverbricks by changing different molds, and honeycomb type block, roadblock and slope block.

Specification:

| Model | QTJ4-15 block making machine |

| host machine size | 3880x1760x2580mm |

| weight | 5000kg |

| motor power | 25kw |

| pallet size | 880*550*25mm |

| forming time | 15-20s |

Production Capacity :

brick type | size(mm) | (pcs/mold) | Cycle forming (s) | (pcs/shift) |

Porous brick | 240*100*60 | 16 | 16-20 | 25600 |

Solid brick | 240*115*53 | 28 | 13-15 | 53760 |

Hollow brick | 390*190*190 | 4 | 15-20 | 7680 |