QTJ4-25 automatic cement brick making machine

QTJ4-25 Brick machine is a medium sized automatic block machine , durable in working and convenient in maintenance.

Advantages :

1. Higher product density. There are double vibrators on the beam of the press head, which can pressing from the bottom and top with strong vibrations. the blocks can be piled up 3-5 layers .

2. Less error. The quality tolerance of the finished product is 0.5mm, with hollow percentage over40%.

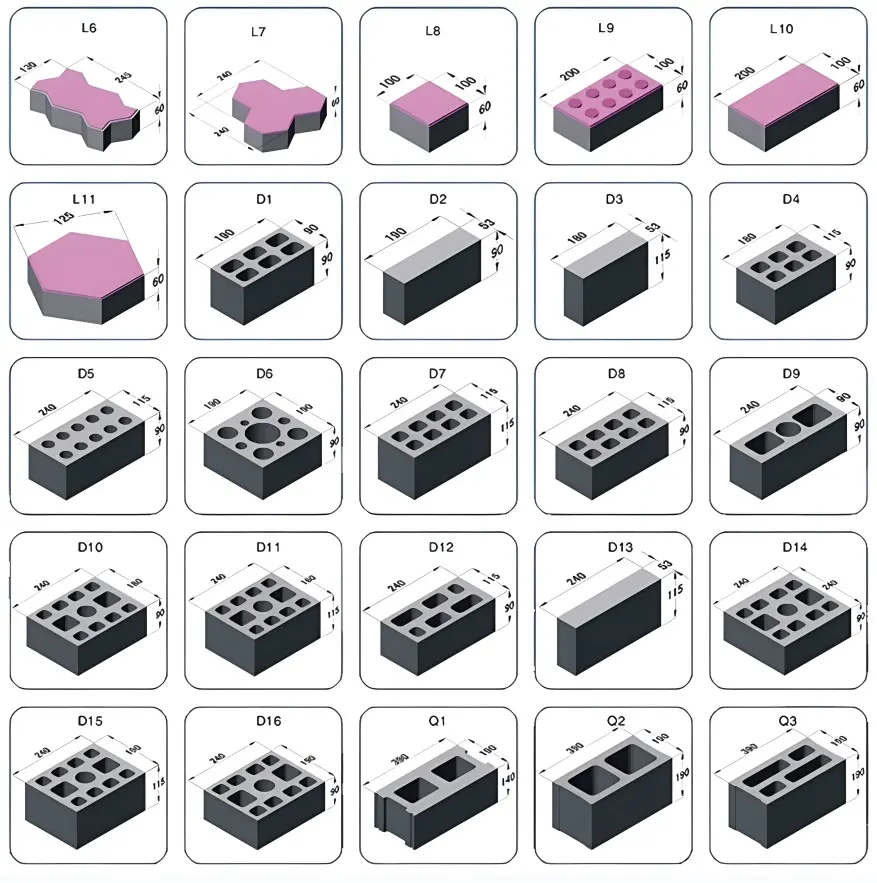

3. Multifunction in one machine. With different moulds, this machine for concrete blocks can be used for producing the wall bricks with different shapes and sizes.

Specification:

| Model | QTJ4-25 brick machine |

| Host machine size | 3580×1960×2200MM |

| Forming time | 20-25s |

| Motor power | 20kw |

| weight | 3500kg |

| pallet size | 850×550×25MM |

Production capacity:

Brick type | Image | Size(mm) | Pcs/Mold | Pcs/Hr |

| Hollow Block |  | 400*200*200 | 4pcs | 480pcs |

| 400*150*200 | 5pcs | 600pcs | |

| Porous Block | 240*115*90 | 12pcs | 1400pcs | |

| Solid Brick |  | 240*115*53 | 26pcs | 3100pcs |