QTJ6-15 automatic concrete brick making machine

The full line including cement silo, batching machine, concrete mixer,automatic concrete brick making machine, stacker machine.the silo stock the cement, conveyor transfer cement into the mixer. the batching machine get a proper compounding ratio for raw material, finally pouring into the mixer hopper and put into the mixing cavity.

The Components of QT6-15 Block Making Machine:

| 1 | B500*8 Belt Conveyor (For Raw Materials) | 1 Set |

| 2 | JS-500 Twin-shaft Concrete Mixer | 1 Set |

| 3 | QT6-15 Block Making Machine host machine | 1 Set |

| 4 | PLC Control System | 1 Set |

| 5 | Spare Parts/Tools | 1 Set |

| 6 | Manual Block-transporting Carts/Push-carts | 2 Sets |

| 7 | Block Mould | 1 Set |

Features :

- Multi-functional blocks manufacturing ,can produce blocks in high density by this high productivity automatic hollow brick making machine.

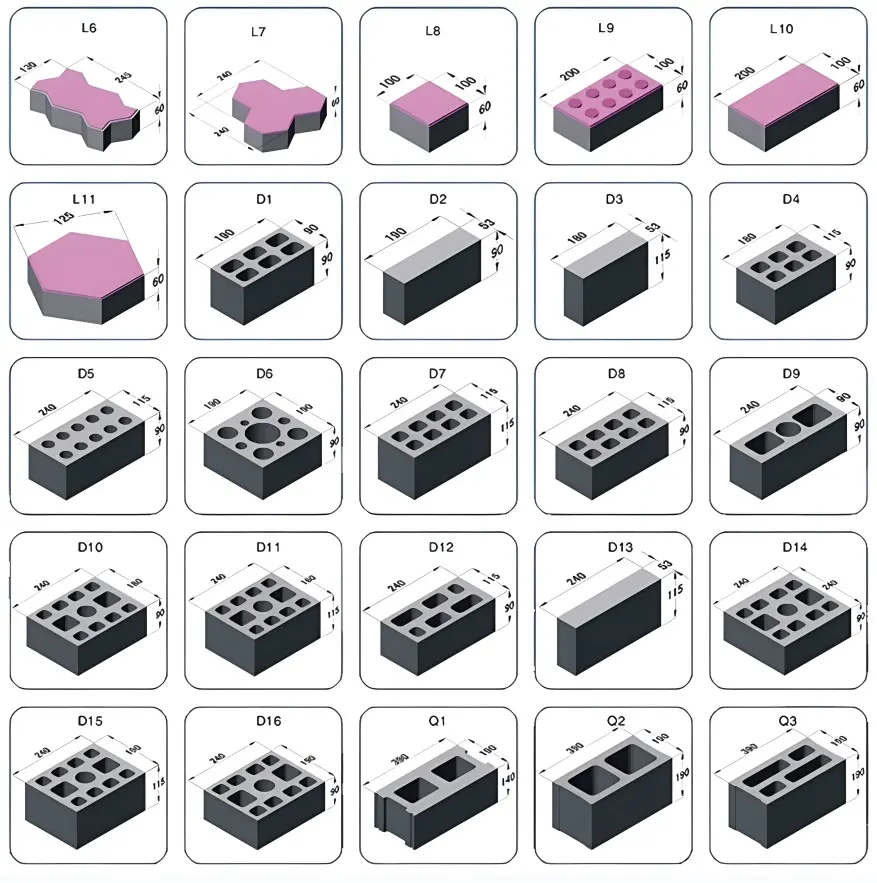

- By changing molds,many kinds of blocks can be made as follows:hollow blocks,holland bricks. curbstone , Standard bricks, Cellular bricks, Grass brick, Decoration bricks, Pavement bricks .

Specification:

Overall Dimension | 7450*2450*2900mm |

Rated Pressure | 16Mpa |

Main Vibration Form | Platform Vibration |

Pallet Size | 900*700mm |

Mould cycle | 15-20s |

Overall power | 32kw |

Weight | 6000KG |

Production capacity :

Brick type | brick size(mm) | (pcs/mold) | Cycle forming (s) | (pcs/shift) |

Color brick | 200*100*60 | 21 | 18-23 | 42000 |

Solid brick | 240*115*53 | 32 | 15-17 | 7800 |

Hollow brick | 390*190*190 | 6 | 20-25 | 10800 |