QTJ8-15 fully automatic hollow brick making machine

The full line including cement silo, batching machine, concrete mixer,automatic hollow brick making machine, stacker machine.the silo stock the cement, conveyor transfer cement into the mixer. the batching machine get a proper compounding ratio for raw material, finally pouring into the mixer hopper and put into the mixing cavity.

Features :

1. Multi-functional blocks manufacturing ,can produce blocks in high density by this high productivity automatic hollow brick making machine.

2. Automatic operation with PLC controller and hydraulic system .

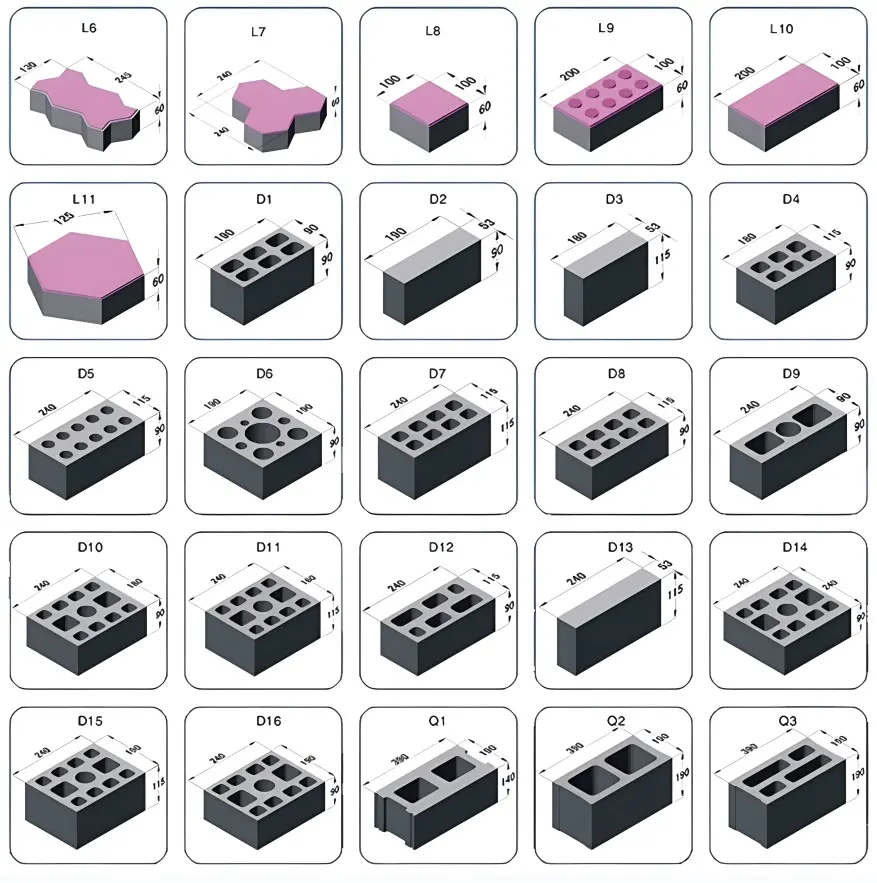

3. By changing molds,many kinds of blocks can be made as follows:hollow blocks,holland bricks. curbstone , Standard bricks, Cellular bricks, Grass brick, Decoration bricks, Pavement bricks .

Technical requested :

- Area: Workshop area: 150-200m2, all factory area 2000m2, the bigger, the better.

- Workers : two or three

- Ratio of raw material:cement 8%-10% sand 30%-40% stone:50%-60%.

- water consumption per day:3%-5% of raw material .

Specification:

| Model | QTJ8-15 Automatic Block Making Machine |

| Host machine size | 3800×2250×2600mm |

| Pallet size | 1060*660*30mm |

| Forming time | 15s |

| Motor power | 45kw |

| Voltage | 220/380v, 50/60hz , 3 phase |

| Weight | 7000kg |

Production Capacity :

Brick type | Size | Cycle forming | QTY/Mold | Per hour | |

Hollow brick | 400*200*200mm | 15–25S | 8 | 1650~1800pcs | |

400*150*200mm | 16–20S | 10 | 1800-2250pcs | ||

Prorous brick | 240*115*90mm | 15–25s | 21 | 4200~5000pcs | |

Solid block | 240*115*53mm | 15-17s | 42 | 9000-10000pcs | |

Color brick | 225*112.5*60mm | 25~30s | 21 | 2520~3020pcs | |