QTJ4-28 cement block making machine

Features:

- Stable performance. vertical vibration and converter brake .the shock on machine can be eliminated .

- Higher product density. There are double vibrators on the beam of the press head, which can press from the bottom and top with strong vibrations. blocks can be piled up to 4-5 layers.

- Less error. The quality tolerance of the finished product is 0.5mm, with hollow percentage over 40%.

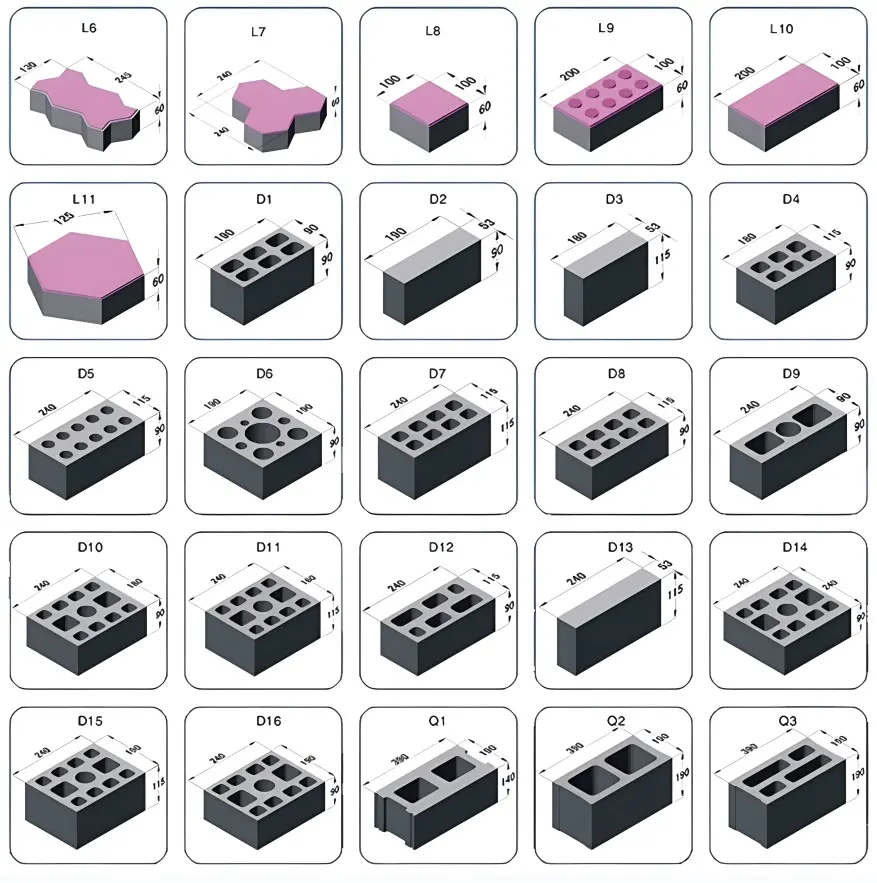

- Multifunction in one machine. With different molds, it can be used for producing the cement blocks with different shapes and sizes by this cement block making machine .

High Density Block

Specification:

| Main Machine | 400 |

| Cycle | 30S |

| Power | 15kw |

| Weight | 3T |

| Pallet size | 850×450×25MM |

| Dimension | 2580×1950×2200MM |

Production capacity :

| brick type | image | size | pcs/8hours |

| Hollow Bricks |  | 390X190X190mm | 4800 |

| Hollow Bricks |  | 240X180X90mm | 14000 |

| solid bricks |  | 240X115X53mm | 33000 |