QTJ4-10 Hydraulic clay brick making machine

It is automatic interlocking clay brick machine is one hydraulic brick machine, as one of best-selling machine, Which can produce lego block, clay brick, cement brick, it is automatic, just equipped with mixer, screen, belt machine. so it is high-efficiency and labor-saving. 2pcs clay bricks/mould.

Advantages:

1, PLC controlled,which can be easily operated by only one person

2,One brick would be made in less than 10 sedonds.

3,Hydorform to guarantee the brick’s density and strength.

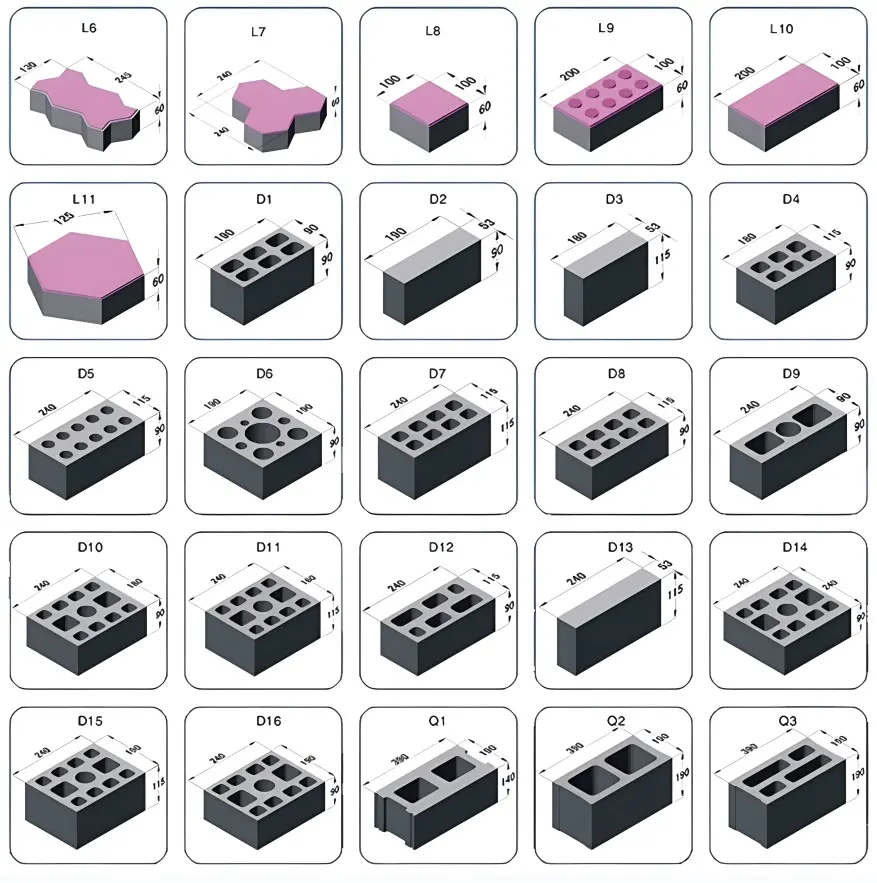

4,Mould can be changed according to cusmer’s requirements.

5,High productivity.

Specification:

| Product Name | QTJ4-10 clay brick making machine |

| Host machine size | 2260x1500x2380mm |

| Molding cycle | 7-10seconds |

| Pressure method | Hydraulic pressure |

| Power | 11kw |

| Pressure | 25-32mpa |

| Total weight | 1300kgs |

| voltage | 220v/380v,50/60hz three phases or as requestment |

Production capacity :

| No. | Block image | Block size | Pcs/mould | Pcs/hour | Pcs/day |

| 1 |  | 250x125x100mm 300x150x100mm | 4 | 800-1000 | 6000-8,000 |

Clay bricks sample :