QTJ4-35 concrete brick making machine

This is concrete block making machine,occupies small space, it is very suitable for small factory or family investment.

Components :

| No. | Items | Function | Pcs |

|---|---|---|---|

| 1 | QTJ4-35 concrete brick making machine | To make the hollow Brick, solid brick and pavement brick | 1 |

| 2 | 6m Belt Conveyor | Transport the raw materials from the mixer to the Brick making machine | 1 |

| 3 | 350 Pan Mixer | To mix the materials: water, sand, aggregate and cement | 1 |

| 4 | Hollow Brick Mould | To make different size and shape bricks by changing moulds | 1 |

| 5 | Manual Cart | Transport the Bricks from the Brick machine to the yard | 2 |

| 6 | Spare Parts Box | Put the Spare Parts (Belt, Bolts, Screws and wires) into it | 1 |

Specification:

Overall Dimension | 1500*1660*2460mm |

Rated Pressure | 16Mpa |

Main Vibration Form | Platform Vibration |

Virbration frequency | 2800r/min |

Pallet Size | 850*450mm |

Mould cycle | 35s |

| motor power | 8.6kw |

Production capacity :

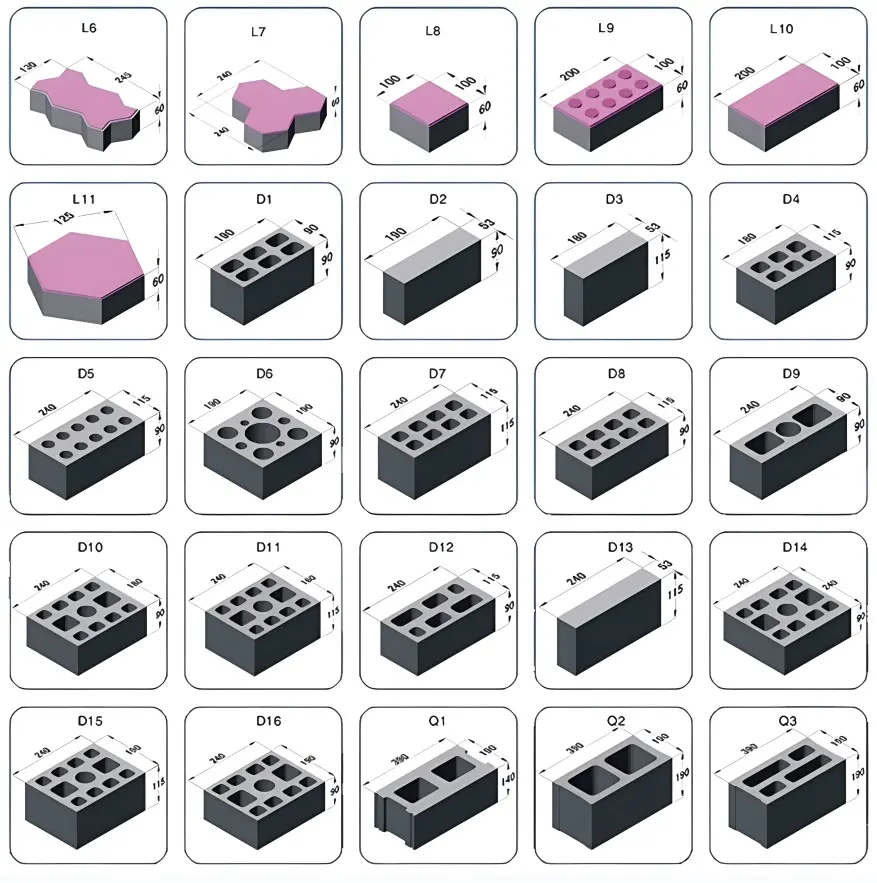

| block image | size | forming time | pcs/mold | pcs/hour |

| 400*200*200mm |  | 35- 38s | 4 | 360 |

| 400*250*200mm |  | 35- 38s | 3 | 270 |

| 240*115*53mm |  | 35- 38s | 18 | 1500 |