QTJ10-10 Hydraulic clay brick press machine

Features:

1, The great innovation is the moulding box will fall down automatically after moulding. No need extra power during this process, a lot of time and labor would be saved. With high Efficiency , less consumption of materials . It is an ideal choice for customer.

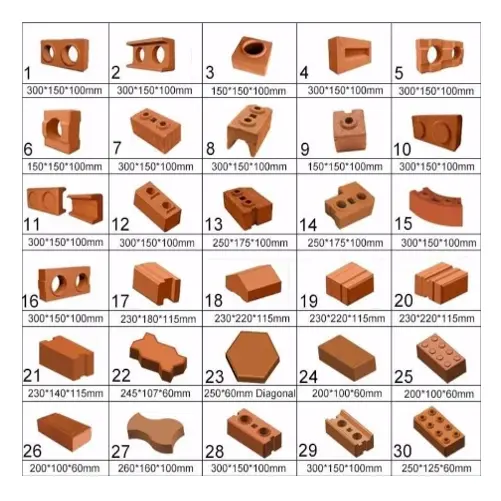

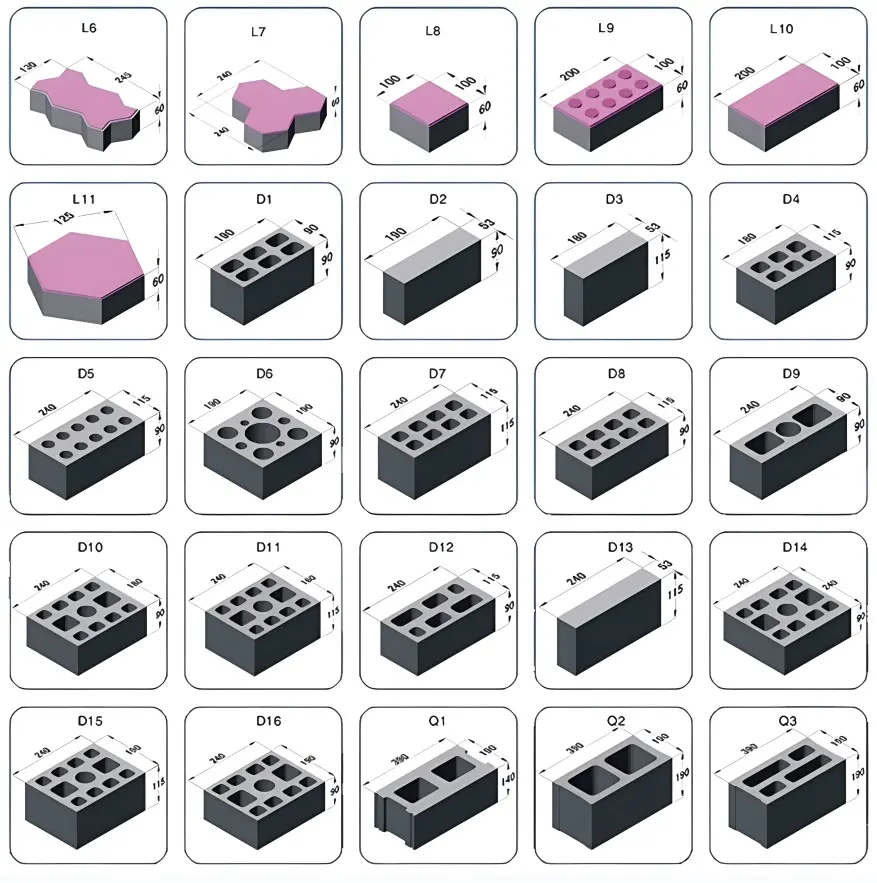

2, This hydraulic clay brick press machine,could generate great pressure,with quickly molding time,making the brick with high density.By changing the molds,all kinds of brick/block/interlocking bricks.

Specification:

Product Name | QTJ10-10 interlocking brick machine |

host machine size | 2860x1500x2380mm |

forming cycle | 7-10 seconds |

forming type | Hydraulic pressure |

motor Power | 18kw |

Pressure | 25-32mpa |

Total weight | 2600kgs |

Rate voltage | 220v-440v, 50/60HZ as request. |

Clay brick samples: