QTJ2-10 Hydraulic interlocking clay brick machine

It is automatic interlocking clay brick machine is one hydraulic brick machine, as one of best-selling machine, Which can produce clay brick, cement brick, it is automatic, just equipped with mixer, screen, belt machine. so it is high-efficiency and labor-saving. 2pcs clay bricks/mould.

Advantages:

1, PLC controlled,which can be easily operated by only one person

2,One brick would be made in less than 10 sedonds.

3,Hydorform to guarantee the brick’s density and strength.

4,Mould can be changed according to cusmer’s requirements.

5,High productivity.

Specification:

| Overall size | 1000(L)×1200(W)×1800(H)mm |

| Forming Cycle | 7-10s |

| Power source | 5KW Motor / 12HP diesel engine |

| Electrical voltage | 220/380v-50/60HZ (Adjustable) |

| Hydraulic pressure | 15-22 MPa |

| Weight | 1000 kg |

| Row material | Laterite,yellow or red soil,sand,cement,water |

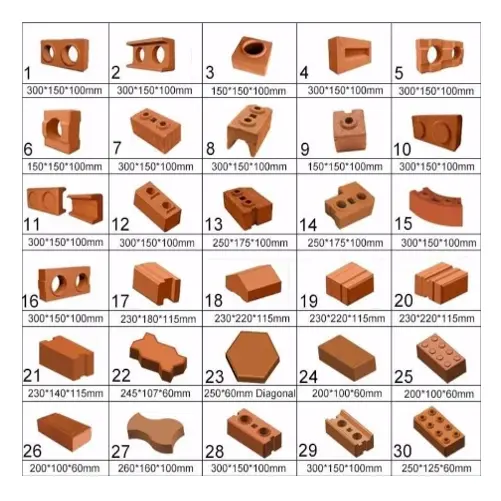

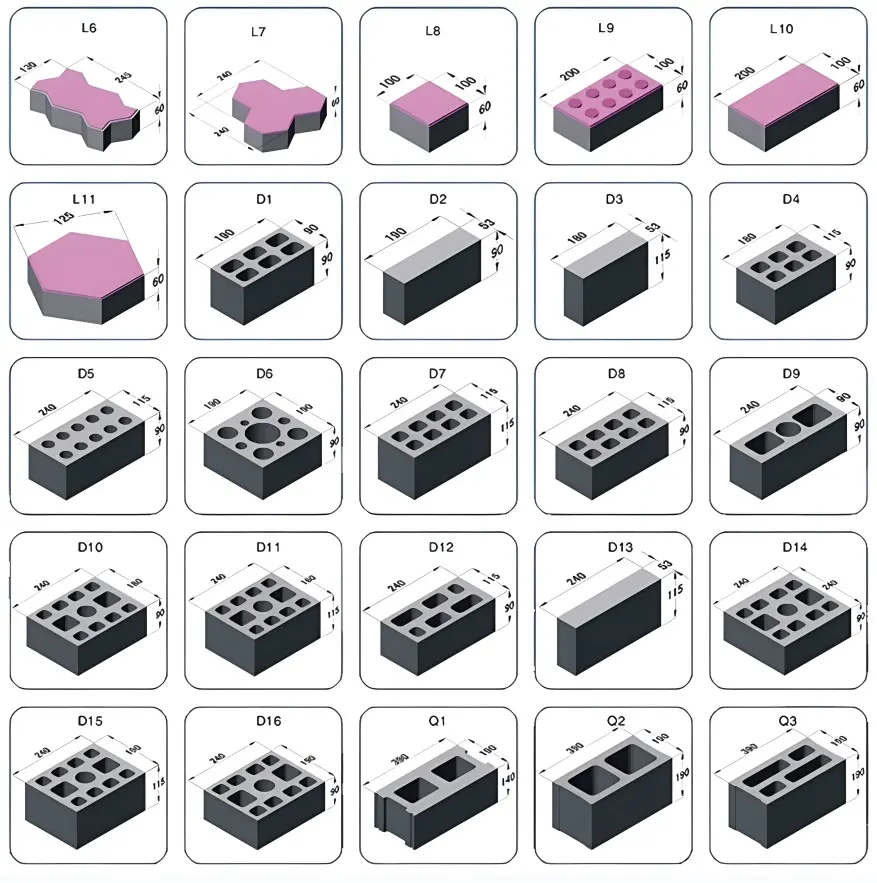

Clay bricks sample:

Production capacity :

| item | brick size | pcs/mold | pcs/day |

| 1 | 250x125x100mm | 2 | 3000-4000 |

| 2 | 300x150x100mm |