QTJ4-26 porous concrete brick making machine

Features :

QTJ4-26 block achine is a semi-automatic block making machine, which included the main machine, concrete mixer, belt conveyor and free one set of mold. It is suitable for small investment ,and very popular in the market

Advantages of porous concrete brick making machine:

- Higher automatization. No need manual feeding of pallets; Available to set up to PLC automatic control; Largely reducing the labour intensity of the workers.

- Reasonable design. All the transmitting system is of mechanical driving so that it is durable in use and convenient in maintenance.

- Stable performance. Due to vertical vibration and converter brake .the after shock on machine can be eliminated at once.

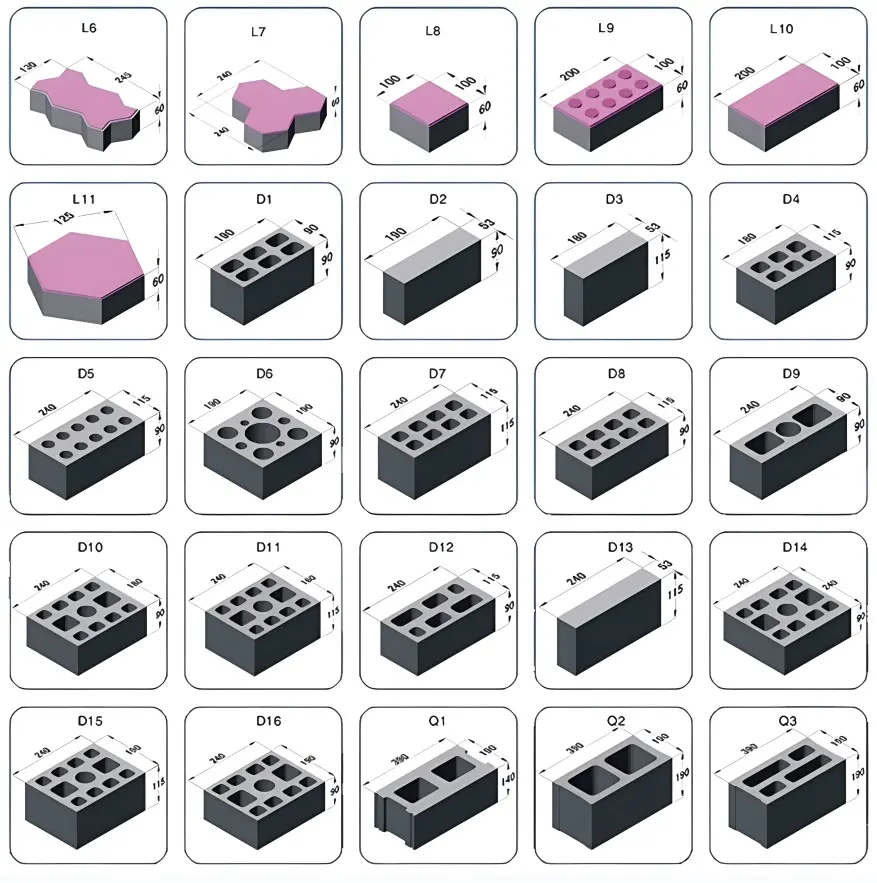

- Multifunction in one machine. With different moulds, it can be used for producing the wall blocks with different shapes and sizes.

Specification:

| Model | QTJ4-26 Block making machine |

| Host machine dimension | 2200x2000x2400mm |

| Forming time | 25 – 30s |

| Weight | 1800kg |

| Motor power | 15kw |

| Pallet size | 850*550*25mm |

Production capacity:

| Block Size | BlocKs/Mold | Blocks/Hour | Blocks/Shift | block type |

| 390x190x190mm | 4 | 580 | 5800 | hollow |

240x115x90mm | 18 | 1400 | 14000 | porous |

| 400x250x200mm | 2 | 288 | 2880 | hollow |

240x53x115mm | 36 | 3300 | 33000 | solid |